Because the structure of auto parts is relatively complex, the precision requirements are relatively high, and even there are many assembly positions, so we first choose good materials to process, because auto parts will be used for a long time after production, so we must ensure that the quality of the product is no problem. of. It is the most time-saving and the most convenient to process auto parts on a five-axis machine tool because the machining surface and accuracy involved are more in order to improve efficiency, save costs and ensure product accuracy. It is suitable for five-axis machine processing. First of all, we choose to Reasonable clamping method ensures the stability during processing.

Because auto parts parts are more complicated, processing on the five-axis linkage machine tool firstly can reduce the number of production fashion clips and save processing time during production. In this regard, it also improves processing efficiency. There are two aspects that need to be paid attention to when processing: First It is the appearance and the second is the quality. To control the appearance, we can choose a better tool for processing. Pay more attention to the details during processing. The pendulum of the fine knife should be set. The speed of the machine should be set. The feed should be set reasonably to ensure that the appearance of the processed product is as good as possible. ok.

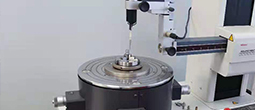

Then when machining the precision hole tolerance or assembly position, first confirm that the tool swing is correct, preferably within 0.01, and then carefully check the added tool compensation value when machining the tolerance. Do not enter the wrong value, if it is a small hole during measurement. Use a plug gauge to measure. If it is a slightly larger hole, you can choose to use a micrometer or an accurate caliper to measure. Before measuring, use a ring gauge to check whether the measuring tool is wrong. As long as the appearance and tolerance range are guaranteed to other complex structures, the advantages of the five-axis machine tool can be used for processing. The most important thing is that the tolerances must not be problematic. Because the auto parts involve assembly and good use, the machining accuracy tolerances must be guaranteed. problem.