Precision machining is technically difficult, has many influencing factors, involves a wide range of areas, has high investment intensity, and has strong product personality. Its main contents are as follows:

(1) Processing mechanism In addition to the precision of traditional processing methods, non-traditional processing (special processing) methods have developed rapidly. At present, the traditional processing methods mainly include diamond tool precision grinding, precision grinding with micro-powder grinding wheels, precision high-speed cutting and precision belt grinding; non-traditional processing methods mainly include high-energy beams such as electron beams, ion beams, and laser beams. Machining, EDM, electrochemical machining, photolithography (etching), etc. And there have been composite processing methods such as electrolytic grinding, magnetic grinding, magnetic fluid polishing, and ultrasonic honing with composite processing mechanisms. The research of processing mechanism is the theoretical basis of precision and ultra-precision processing and the growth point of new technology.

(2) Material to be processed Precision mechanically processed material to be processed has strict requirements on chemical composition, physical and mechanical properties, chemical properties, and processing performance. It should have uniform texture, stable performance, and no macro or micro defects outside and inside. Only the processed materials that meet the performance requirements can obtain the expected results of precision machining.

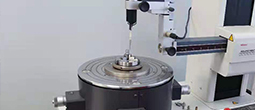

(3) Processing equipment and process equipment Precision machining should have high-precision, high-rigidity, high-stability and automated machine tools, corresponding diamond tools, cubic boron nitride tools, diamond grinding wheels, cubic boron nitride grinding wheels. And the corresponding high-precision, high-rigidity fixtures and other process equipment can ensure the processing quality. Precision machining should first consider precision machining machine tools with corresponding accuracy. Many precision machining often start from designing and manufacturing their ultra-precision machine tools. And to configure the required tools. At present, there are few general-purpose series of precision machining machine tools. The batch will not be large. The cost of precision machinery national machine tools is very high, and special orders are required, if the processing on the existing precision machining machine tools cannot meet the requirements. The processing accuracy can be improved through technological measures or error compensation.

(4) Inspection Precision machining must have corresponding inspection technology to form an integration of processing and inspection. There are three methods for the inspection of precision machining: offline inspection, in-position inspection and online inspection. Offline inspection refers to sending the workpiece to the inspection room for inspection after the processing is completed; in-position inspection refers to the on-site inspection without removing the workpiece after processing is completed on the machine tool. If any problems are found. It is convenient for further processing; on-line inspection is to inspect during the processing, so as to be able to actively control and implement dynamic error compensation.