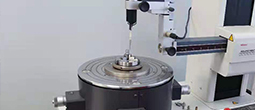

The working principle of CNC precision parts processing can generally control the machine tool according to the numerical sequence instructions to realize the automatic start and stop of the spindle, reversing and speed change. It can automatically control the feed speed, direction and processing route for processing. Able to select the tool and adjust the amount of cutting and walking path according to the size of the tool, and can complete various auxiliary actions required in processing. The structure of CNC precision parts processing CNC lathe is also composed of headstock, tool post, feed transmission system and bed. Hydraulic system, cooling system, lubrication system and other parts are just the essential difference in structure between the feed system of CNC lathe and the feed system of horizontal lathe.

The advantages of CNC machining are summarized. Nowadays, many parts are processed by CNC. The reason for this situation is that CNC machining has many superior characteristics, not only easy to operate, but also good in processing effect. It is precisely because of this that the CNC precision parts processing industry has attracted so much attention. So do you know the specific advantages of CNC machining? The advantages of CNC processing can be summarized in four main points: 1. Direct use of engineering plastics, low material costs, and a wide range of materials. 2. The machine equipment has stable performance and simple operation. 3. The parts can be properly decomposed. 4. It is especially suitable for processing large size and relatively simple structure parts.