Precision machining technology has developed rapidly in terms of improving accuracy and productivity. In terms of increasing productivity, increasing the degree of automation is the direction that countries are committed to development. Precision parts processing has developed rapidly from CNC to CIMS in recent years, and has been applied within a certain range. From improving precision, from precision machining to ultra-precision machining, this is also the direction of development of major developed countries in the world.

(1) Technical and technological advantages of precision machining

Compared with the roomless process, the advantages of precision machining and cutting work are firstly that it has a high material removal rate and good economy. For example, compared with laser plasma processing technology, this is because of this. At present, only a large supply of this technology can achieve a high material removal rate. On the other hand, there are still questions about whether the processed workpiece can meet the requirements of size and shape accuracy. Chipless pressure machining is mainly used for mass production, and often requires subsequent cutting to obtain the final qualified shape of the workpiece. Therefore, the main advantage of machining is to enable the workpiece to achieve higher accuracy. Precision machining is widely used, especially with the development trend of small batch production, the shape and dimensional accuracy of workpieces are becoming higher and higher, which has opened up a new and more extensive field for precision machining. The use of lathes naturally requires various turning processes, but it should also be noted that the machining processes such as drilling, milling, grinding, and gear cutting can all be done on one lathe (process integration). This is the trend now developed. The machining method of the compound machine tool of the turning and milling machining center. Dongguan precision machining

(2) Precision machining methods

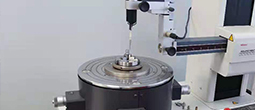

According to the mechanism and characteristics of the machining method, precision machining can be divided into four categories: tool cutting, abrasive machining, special machining and compound machining.